Lathe page 5

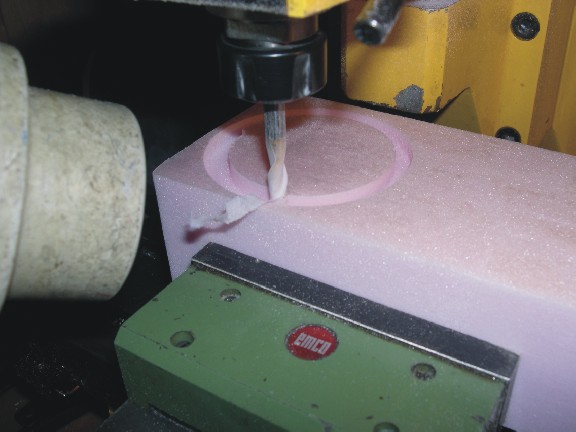

June 27 I spent most of the day milling a pattern out of foam for the compound slide that gets mounted to the crosslide

I spent some time writing the program and forgot to use the

radius on the center hole the first time so had to redo it.

But I got it right the second time

Here the machine is clearing the relief area after cutting the wear pad

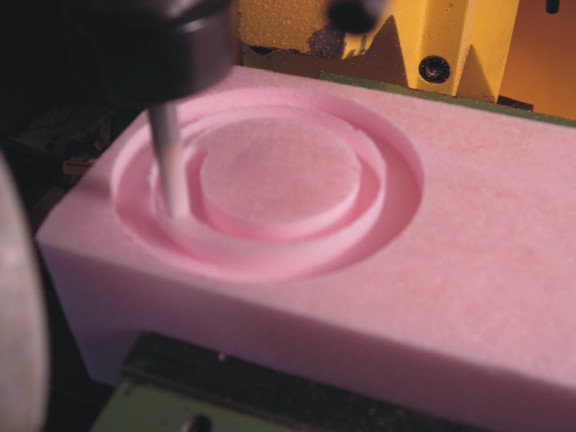

here I'm cutting the wear pads that will rest on the crosslide ways

Heres the pattern sitting on the crosslide

Getting ready to cast. when using the lost foam method be

sure to use DRY sand and vibrate the box so that the

sand gets in and under every bit of the part. Just

use a hammer and bang the side of the box and you can see the sand

move around.

I am so impatient the part had not cooled 10 minutes and

I pulled it from the sand. I cut the sprues

within another 10 minutes and had it sanded and smoothed

out before I could hold it in my

bare hands. As You can see in the background this was not my first attempt,

and I made another

after this with the sprue in the light end of the compound and placed on end

in the flask so the

aluminum had a straight shot to the heavy end.