Lathe page 2

06-14-04

Well its been a few months and I've learned a few things.

after building the patterns the project sat for a while and then I got into

a metal melting mood a month or so ago so I went gangbusters on the foundry

and made a lot of castings and a lot of mistakes.

I also enrolled in a machine shop class at the local college

and learned a little about working with metal working machines,

mainly the lathe and milling machine. I'll probably be going back in the fall

and get some more learnin'.

After trying numerous times to get a good green sand mold

I gave up and researched on the net and discovered

lost foam casting so I remade the bases and bed in foam using my drillpress

and a groud drill bit as a mill

This is my first casting and I surprised myself it actually came out!

Heres the first casting and the next foam pattern with risers

Heres the riser looking down through the sprue. next time

I will slope the sand towards the casting. molten aluminum

causes wood to ignite, who woulda thought?

Heres a wider angle shot

This is the foam casting not so hot (literally, the aluminum

was too cool). Bummer it took two or more hours

to mill it and only 10 seconds to kill it.

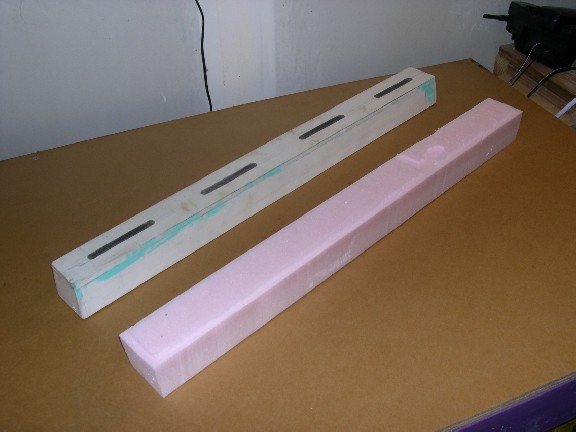

So I did a little more research and found an englishmans

website and he suggested making a solid pattern

and a corebox to make the cores

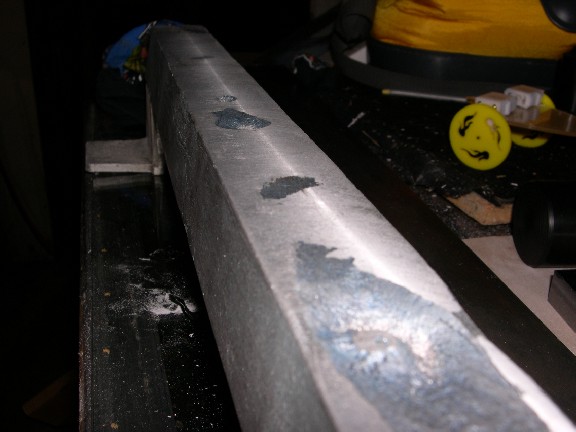

Heres the casting.....

But its not to be, yet. so I tried it again and this time

it worked good enough and by this time I was

far enough in my class to finish off the bed at school.